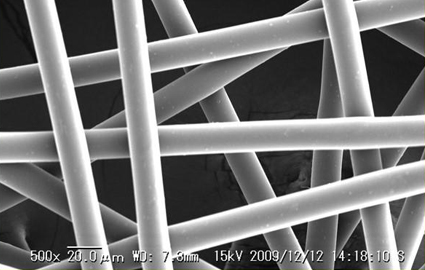

The definition of ‘Nano’ means it is one billionth of a meter. This size is equivalent to the size of three to four molecules. Generally, nanofibers are in the range of 100nm - 200nm and specifically in the textile industry, such definition is extended to include fibers up to 1000nm diameters. 1 gram of fiber with a diameter of 200nm can reach up to 300,000km in length, which is equivalent to 3/4 of the Earth’s circumference.

Nano Membrane

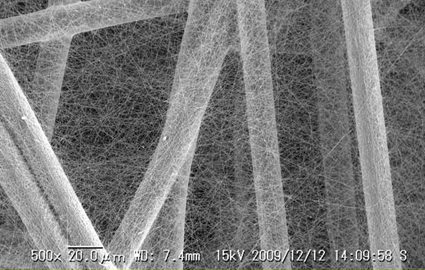

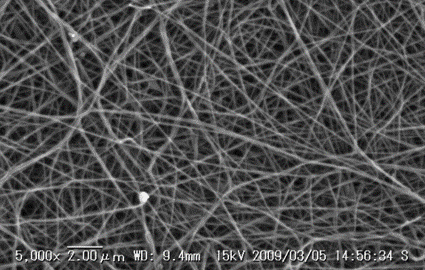

Nano membrane is a 3 dimensional network composed of stacked web of nanofibers. Such nanofibers coatings and nano membranes are produced through proprietary electrospinning process using various polymers. The interconnected and porous nanofibers have enormous surface area for its volume and has shape of a mesh.

Due to these unique features, it is very thin and light weighted. It also has high penetrability and permeability, but is also effective at resisting liquid and wind. These properties are particularly advantageous for high efficiency filter materials, energy storage materials, tissue engineering, biomedical application, micro-electronic mechanical system materials, nano complex materials and other applications.

Further, by applying nano membrane to regular textile, it enhances functionality to be used as technical textiles in various application.

Characteristics of Nanofiber

* Filtration (Nanofiber Filter Media)

- 100% compliance to the stricter EN779 and EN1822 Standards: Departing from existing electrostatic technology and applying unique characteristics of nanofiber to achieve mechanical filtration property.

- Substitution for Glass Fiber: Resolve environmental and hazardous issues caused by glass fiber.

- A solution to Global Warming and Environmental Pollution: Increased demands for high efficiency filters to save energy

- Ability to be used as high efficiency industrial air and liquid filters: Compared to conventional filter media, it offers much higher efficiency at a significantly lower pressure drop.

Nano Membrane is a 3 dimensional network composed of stacked web of nanofibers. Such nanofibers and nano membranes are produced through proprietary electrospinning process using various polymers. The interconnected and porous nanofibers have enormous surface area for its volume and has shape of a mesh. Due to these unique features, it is very thin and light weighted. It also has high penetrability and permeability, but is also effective of resisting liquid and wind.

These properties are particularly advantageous for high efficiency filter materials, energy storage materials, tissue engineering, biomedical application, micro-electronic mechanical system materials, nano complex materials and other applications. Further, by applying nano Membrane to regular textile, it adds functionalities to be used as technical textiles in various application.

-

Conventional Filter Media

-

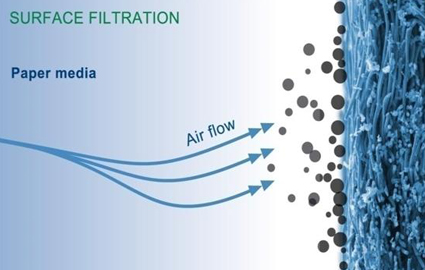

Nanofiber coated filter media

When nanofiber is applied to the surface of the media, the surface effectively traps dust and pollutants. The surface of the filter can be easily cleaned by pressurized back pulsing air or by simply shaking it. As the dust particulates do not pollute the substrate easily, the lifespan of a filter can be extended by cleaning repetitively through the described methods above.

-

Particles deposit on the surface

-

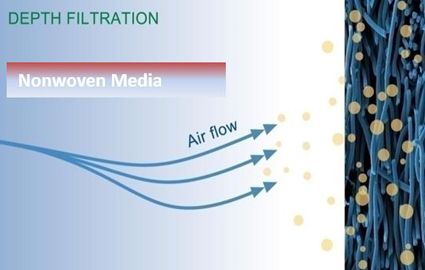

Particles deposit in the media

Unlike the glass fibers which are hazardous when inhaled, nanofibers, manufactured through electrospinning, does not break nor detach from the filter into the air.

Conventional filter requires frequent replacement as impurities gets trapped within the filter substrate. However, Lime nanofiber coated filter media can delay the maintenance period by trapping the impurities on the surface, therefore reducing the filter maintenance cost.

Depending on customer’s demand, it is possible to customize additional properties such as heat resistance, fire retardancy and chemical resistance.

※ Nanofiber surpasses almost all types of synthetic and glass fiber media’s filtration properties. Especially, the nanofibers achieve mechanical filtration and the level of innovation allows for a new trend for filtration technology and be applied to various industries.

In past decades, electrostatic charge has been used to enhance traditional properties infilter media substrates. The advantage of adding an electrostatic charge is to lower pressure drop and hence improve energy efficiency. However, these electrostatic filters lack the capacity to effectively filter fine pollutants mechanically due to the pore size which is larger than the target particulates. While electrostatic media shows initial effectiveness, as time goes by, the static perfomance deteriorates significantly reducing small particulate filtration efficiency.

Hence, EN779:2012 outlines new standards of filtration efficiency and use of true mechanical fiiltration. It also requires that projected discharged efficiency must be reported and considered when determining the filtration classsification.

| Group | Class | Final pressure drop (test) Pa | Average arrestance (Am) of synthetic dust % | Average efficiency (Em) for 0.4 μm particles % | Minimum efficiency for 0.4 μm particles % |

|---|---|---|---|---|---|

| Coarse | G1 | 250 | 50≤Am<65 | - | - |

| G2 | 250 | 65≤Am<80 | - | - | |

| G3 | 250 | 80≤Am<90 | - | - | |

| G4 | 250 | 80≤Am<90 | - | - | |

| Medium | M5 | 450 | - | 40≤Em<60 | - |

| M6 | 450 | - | 60≤Em<80 | - | |

| Fine | F7 | 450 | - | 80≤Em<90 | 35 |

| F8 | 450 | - | 90≤Em<95 | 55 | |

| F9 | 450 | - | 95≤Em | 70 |

The new European standard is based on counting particles and such standard fulfills requirements of various fields. EN1822:2009 differs from the previous EN1822:1998 by the following:

- A test procedure for leakage testing of H-Group Filters of various shapes, other than the square panels.

- A test procedure using aerosols, instead of liquid.

- A method to test and classify filter media consisting of membrane-types.

- A method to test and classify filter media consisting of synthetic fibers.

The main difference between two standards is related to the classification of H10-12 filters, (previously E10-12). The following table shows the different classification of high efficiency filters under EN1822.

| Integral Value | Local Value | |||

|---|---|---|---|---|

| Filter Class | Collection Efficiency % | Penetration % | Collection Efficiency % | Penetration % |

| E10 | 85 | 15 | - | - |

| E11 | 95 | 5 | - | - |

| E12 | 99.5 | 0.5 | - | - |

| E13 | 99.95 | 0.05 | 99.75 | 0.25 |

| E14 | 99.995 | 0.005 | 99.972 | 0.025 |

| E15 | 99.9995 | 0.0005 | 99.9975 | 0.0025 |

| E16 | 99.99995 | 0.00005 | 99.99975 | 0.00025 |

| E17 | 99.999995 | 0.000005 | 99.9999 | 0.0001 |

※ Filter Categorization / Class Categorization

EPA 10 - EPA 12 : Efficient Air Filter

HEPA 13 - HEPA 14 : High Efficient Air Filter

ULPA 15 - ULPA 17 : Ultra High Efficient Air Filter

The testing procedure under EN1822 is composed of an aerosol probe which examines throughout the movement of entire surface of the filter. The aerosol probe scans and examines by moving along the surface of the filter and measures sectional efficiency. By measuring sectional efficiency, it allows overall calculation of efficiency or identifying potential leakage rate. Calculation of overall efficiency indicates the entire filter’s value and leakage rate indicates sectional value. The tests are performed by applying specific volume of airflow onto the new filters. For the following test, U15 class or above must pass the particle counter probe.

Filter testing procedures includes the following measurements:

1. Pressure drop during normal airflow

2. Overall filtration efficiency of the most penetrating particle size (MPPS)

3. Partial filtration efficiency of the most penetrating particle size

4. Test of leakage of filters above H13

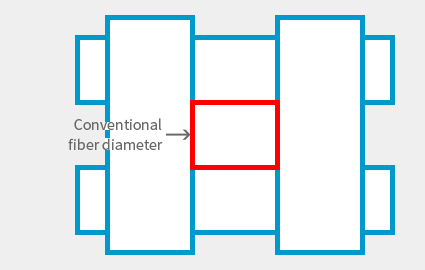

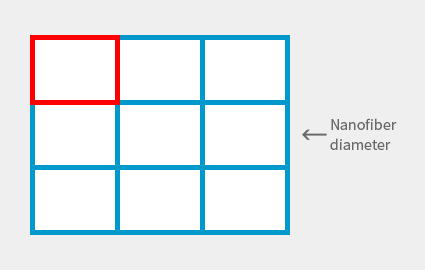

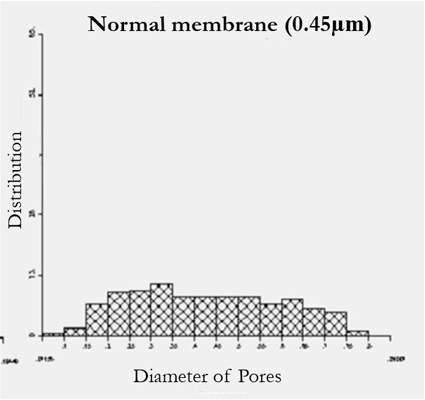

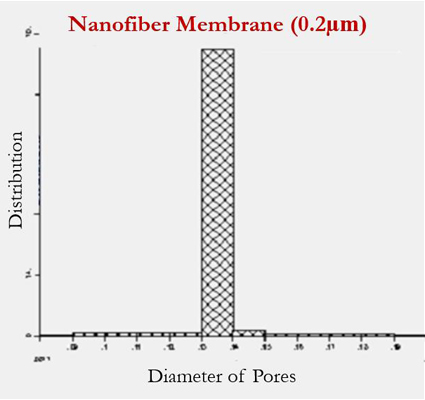

Lime’s products have larger filtration surface area compared to conventional micro filtration’s membrane or felt allows for excellent flow rate. Also nanofiber’s unique physical and mechanical performance allows precise and persistent filtering functions.

-

Conventional filter media with conventional fibers

Number of pores within the same surface area = 1 -

Nanofiber applied filter media

Number of pores within the same surface area = 9

When nanofiber is applied to the surface of the media, the surface effectively traps dust and pollutants. The surface of the filter can be easily cleaned by pressurized back pulse air or by simply shaking it. As the dust particulates do not pollute the substrate easily, the lifespan of a filter can be extended by cleaning repetitively through the described methods above.

-

1,000times

-

5,000times

-

-

-

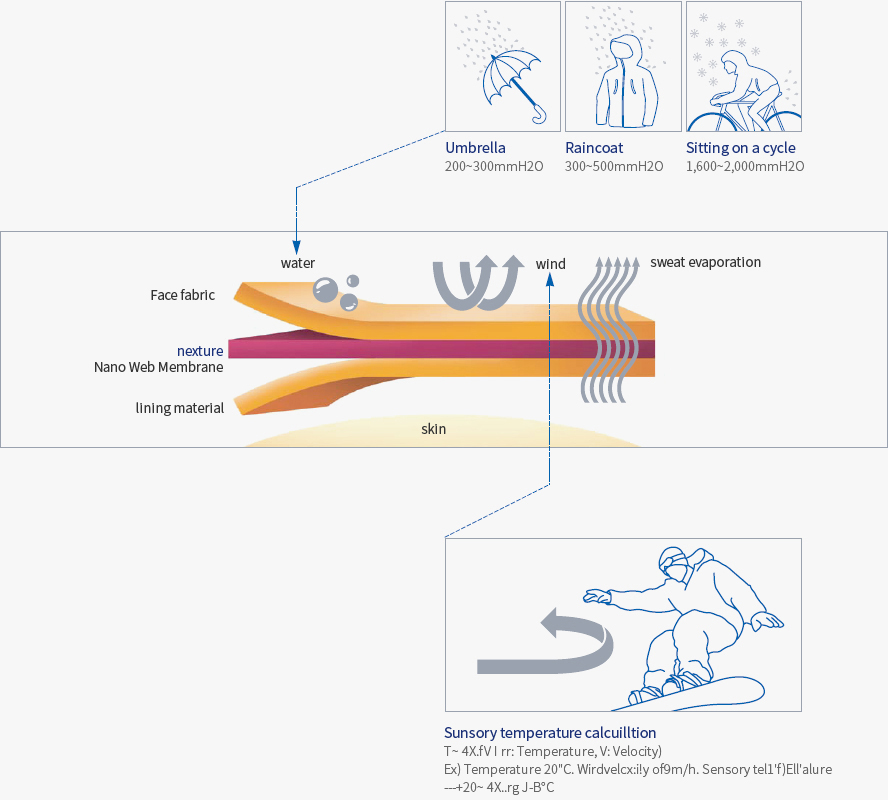

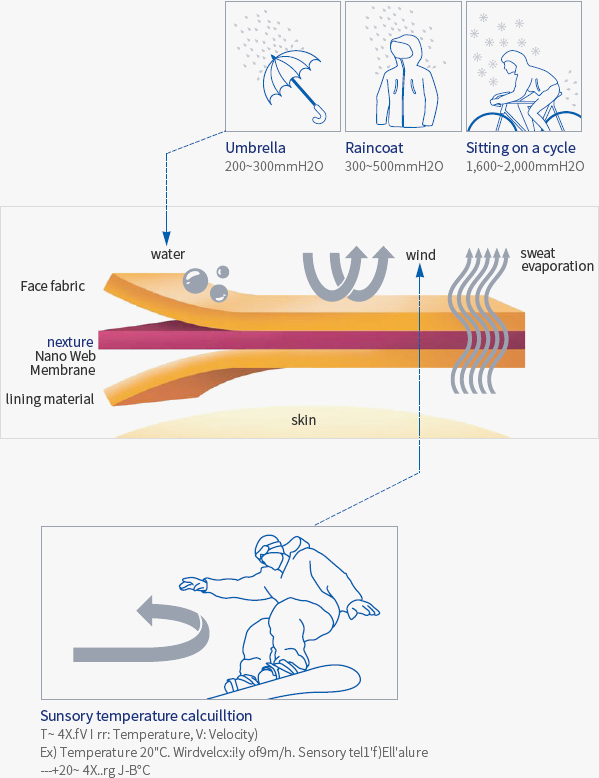

- WATERPROOF

The fabric will not absorb rain or snow during outdoor activity.

Nexture provides excellent waterproofness as the average

pore size of Nexture is 10,000 times smaller than the size of

a water droplet.

-

- WINDPROOF

By completely blocking out the cold air from outside,

it helps to maintain comfortable body temperature.

Also, Nexture’s porous structure becomes an insulating material

for heat insulation between the cloth and the body, which helps

to maintain suitable body temperature.

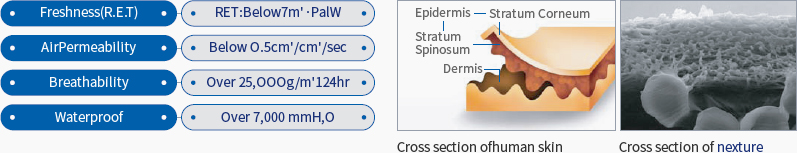

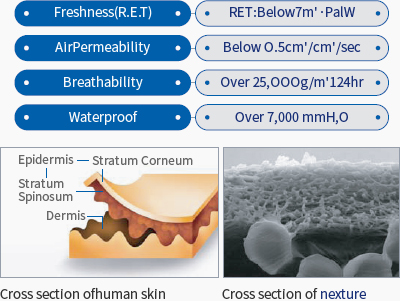

Nexture's operating mechanism is similar the human skin allowing you to experience comfort like never before.